Introduction of the Electronic Certification System (ECS)

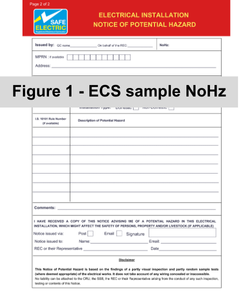

With the introduction of the new Electronic Certification System (ECS), Registered Electrical Contractors (RECs) can now issue an electronic Notice of Potential Hazard (NoHz) directly through the ECS platform.

Situations may arise where a REC carrying out installation works observes a potential hazard. The potential hazard may not be associated with the REC’s contract of works. A REC has a duty of care to inform the electricity consumer of any immediate or potential hazard.

If the customer or REC is not in a position to rectify the hazard, the REC should issue a NoHz. The NoHz shall specify the associated National Rules for Electrical Installations (I.S. 10101) rule breach number(s), and a brief description of the hazard.

When issuing a NoHz, the REC or their Representative needs to ensure that the issue observed is not only a breach of the national wiring rules but that it is a hazard (safety issue), as not all rule breaches would be classed as a hazard.

This new ECS system allows the REC to generate the NoHz in electronic format. This is automatically converted to a PDF and can be emailed directly to the customer. Additionally, the digital version of the NoHz is securely stored in the REC’s ECS account, ensuring it is always available for reference in the event of an incident or audit. Another advantage of the new platform is that Safe Electric will be directly informed and there is no need for the REC to send a copy in the post.

Ideally, RECs should identify and communicate any hazards present in the existing installation prior to proceeding with any major modifications.

Issuing a NoHz

When a REC encounters a potential hazard, the first step must always be to inform the customer. If the customer agrees to the required remedial work, the potential hazard should be rectified or disconnected from the supply. Otherwise, the REC must issue a NoHz. This document formally notifies the customer of the identified risk and recommends them to engage a REC to undertake the necessary remedial action.

A copy of the notice must be:

- Provided to the customer, and

- If using paper format, submitted to Safe Electric.

Upon receipt, Safe Electric will follow up with the customer to ensure they are aware of the issue.

⚠️ Please note: A NoHz should only be issued for a hazard (safety issue) that may be potentially harmful. Not all rule breaches are safety issues.

Clause 6.4.1.5 & 134.1.9

Clause 6.4.1.5 & 134.1.9 of the wiring rules states that the REC must assess the suitability of the existing installation for any new additions or alterations. This means that before an addition or alteration, the REC must evaluate the current installation and take into account additional work that may be required to ensure the addition or alteration complies with I.S. 10101.

For example, if installing a large load such as a 9.5 kW shower to an installation with 6 mm2 mains tails, the mains tails will need to be upgraded to 16 mm2. The main protective conductor (to the PEN), the earthing conductor (to the earth electrode), and the main bonding conductors may need to be upgraded also, if undersized.

In the example above, this additional work must be carried out before connecting the electric shower. It is not sufficient to simply issue a NoHz for a part of the existing installation that impairs the safety of the new installation or vice-versa.

NoHzs are to be used to highlight to the customer existing potential hazards that the REC has discovered that do not directly impair the REC’s own work.

The Importance of the NoHz

The NoHz is an important document for RECs. It ensures that:

- The customer is fully informed, and

- Safe Electric is aware of the issue.

Do’s and Don’ts of Issuing NoHzs

✅ Do:

- Always assess the existing installation.

- Always inform the customer of any potential hazards as soon as they have been identified.

- Always carry a booklet of NoHzs, or have access to your ECS platform.

- Include the rule number or clause associated with the non-conformance in the notice.

- Always give the notice to the property owner or the person responsible for the premises. If unavailable, the notice may be left on-site or posted to the address.

- For immediate and serious hazards, inform your local inspector, who may issue an emergency works notice.

- Do contact your local inspector if you require more guidance.

- Do refer to the Safe Electric Notice of Hazard & Emergency Works Procedure on the Safe electric website

❌ Don’t:

- Don’t start works without assessing the existing installation.

- Don’t wait. Issue the NoHz as soon as the hazard has been identified.

- If using paper format, don’t forget to send the NoHz to Safe Electric.

Most Common Hazards Recorded

1. RCBO/RCD Faults

When carrying out any upgrades, current Safe Electric guidance is to test all RCDs and RCBOs within the affected distribution board. This ensures that all devices are functioning correctly and helps identify any faulty or non-operational devices, which could pose a serious safety risk if left undetected.

2. Exposed Live Parts

Existing installations which contain exposed live parts, present a significant electrical safety hazard. Watch out for missing blank covers on distribution boards. If an emergency works notice is required, consult your Inspector

3. Insulation Resistance Fault

Existing installations with low insulation resistance readings could indicate potential deterioration or damage to the cable insulation.

An overall (or individual circuit) insulation resistance test that shows a direct short between conductors may indicate a neutral to earth fault on an existing non-RCD protected circuit.

4. Undersized Conductors

Existing installations with undersized conductors. For example, a 6 mm² PVC/PVC mains tails cable supplying an entire dwelling that includes an instantaneous electric shower.

5. Earth Rod Not Available for Inspection

In some cases, it is discovered that an earth electrode (earth rod) was never installed as part of the original installation.

In other instances, while an earth rod may have been installed, it was subsequently concealed and cannot be visually verified. In these situations, the test described in Annex 6C.2 of I.S. 10101 may be carried out in order to verify the earth resistance. See Table 53.1 for maximum values of earth resistance.

6. Neutralising Issues

In Ireland, the Distribution System Operator (ESB Networks) specifies the earthing arrangement (typically TN-C-S) which is designed to ensure automatic disconnection of supply in the event of a fault by providing a low-impedance path for fault current. This allows protective devices to operate effectively.

However, in some cases, this critical PEN connection (neutralising link) was never installed or has been removed. A clear indication of a missing PEN connection is a high L-E fault loop impedance reading (Zs). As a result, some circuits may be left without any fault protection. This is a serious potential hazard and should be rectified as part of any addition or alteration to the existing installation.

If the customer refuses this remedial work, no additional electrical work should be carried out on the installation and a NoHz should be issued to the customer recommending that remedial action is undertaken by a REC as soon as possible.