RECs working on installations which are more than 10 years old shall issue a recommendation that an Electrical Installation Condition Report (EICR) or Periodic Inspection Report (PIR) shall be carried out. It should be noted in the comments box on the certificate that this recommendation has been issued.

RECs working on existing distribution boards or upgrading customer meter tails or certifying MIC increases, shall take cognisance of the installation in its entirety. A Test Record Sheet shall be completed for the new work and the following non-exhaustive, items shall be reviewed while undertaking this work:

- Visual Inspection of existing installation.

- Verify Polarity.

- Adequate size of meter tails.

- Main Protective Conductor Continuity Verified (Neutralising Link).

- Earthing Conductor (to Earth Electrode) Continuity Verified.

- Main, Supplementary, and local equipotential bonding verified.

- Check terminals are tightened to correct torque (Refer to Manufactures instructions).

- Ensure fuse Carriers are tight and correct gauge rings are fitted.

- Avoid cut outs in distribution board covers and utilise top/rear entry for routing of new cables.

- Ensure all voids are appropriately fitted with blanking plates.

- Ensure that withdrawn or notified faulty devices are replaced (DZ3 fuses and faulty switchfuses).

- Ensure RCDs / RCBOs are in place where required.

- Verify / Test operation (Trip Time) of all existing RCDs and RCBOs in line with the wiring rules (These tests should be completed prior to the circuits being placed back into service).

- Carry out an overall Live + Neutral to Earth Insulation Resistance test at 250 volts to ensure that an existing Insulation Resistance fault does not impair the safety of the new work. (Rule 6.4.1.5 of the Wiring Rules, as shown below).

Should any of the above or other hazards identified remain to be sub-standard, the REC shall either rectify the problem or issue a Notice of Potential Hazard form to the customer, as per Section C clause 4.7 page 76 of the criteria Document, and proceed with the certification of the new works.

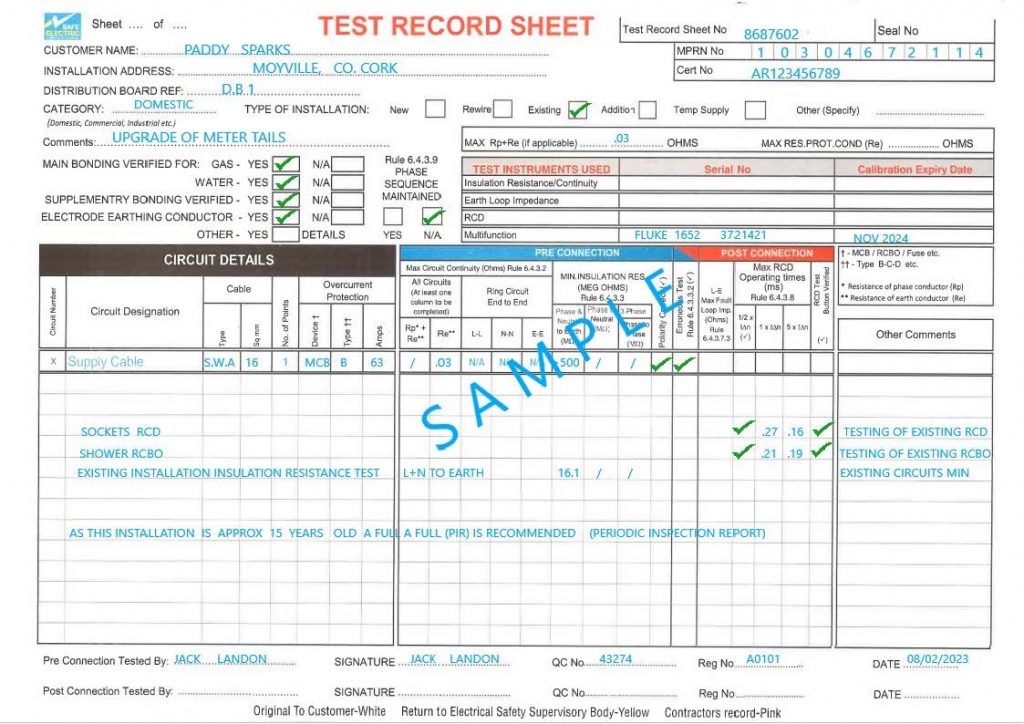

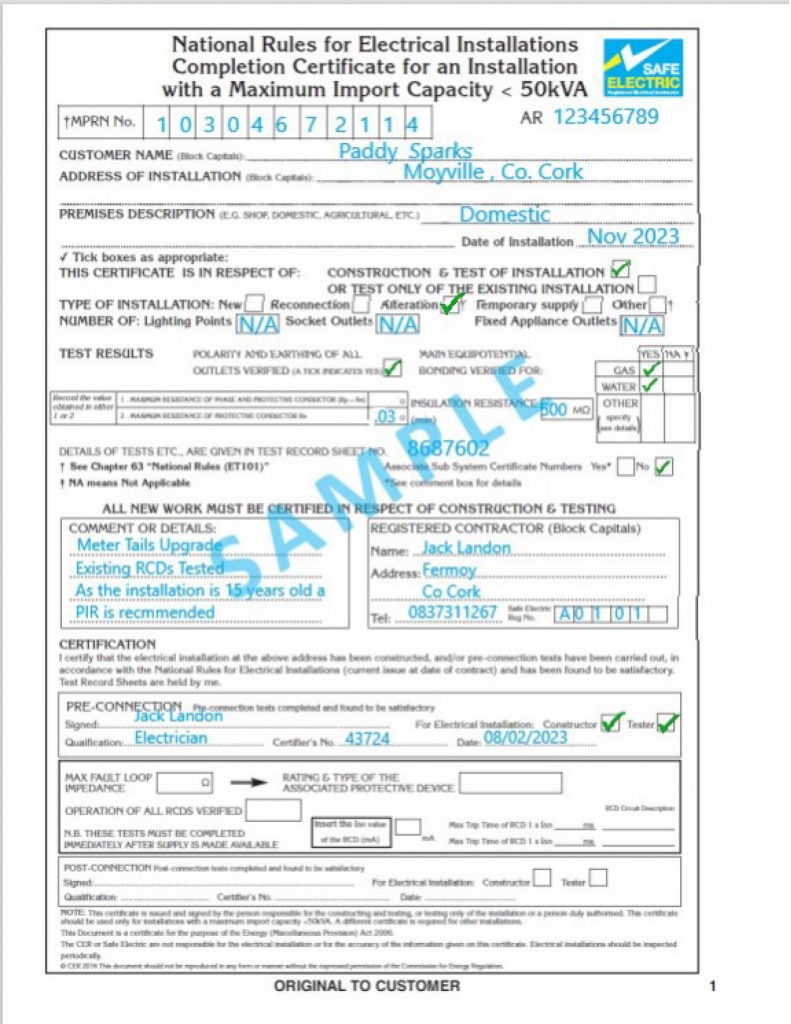

When completing certificates RECs are required to insert the relevant values for Insulation Resistance, fault Loop Impedance, ZE and RCDs / RCBOs trip times. These values shall be transcribed from the associated Test Record Sheet. Where Test values are for existing circuits and not installed by the REC, the test values shall be entered on the Test Record Sheet and a note entered in the comments section advising the results are for existing circuits.

See below a sample of a Test Record Sheet:

Example: The installation or removal of a lifestyle choice prepayment meter or the replacement or modification of customer meter tails that requires the supply to be de-energised, disconnected, reconnected and re-energised. This will require testing of downstream devices and the relevant data recorded on an associated Test Record Sheet and transcribed onto the accompanying Certificate.

This includes all tests as listed in I.S. 10101 the National wiring rules, for example, Insulation Resistance test of the existing and the new cables installed. Supply Loop impedance, Ze, testing of trip times of RCDs, / RCBOs downstream of the new/modified works and polarity verified.

The inclusion of N/A ensures that a box on the certificate cannot be left blank or empty. It is not a means for a REC to avoid performing a test.

See below a sample of The National Rules for Electrical Installations Completion Certificate:

Commercial / Industrial / Agricultural Electric Installations

RECs working on installations in the categories above, shall issue a recommendation that an Electrical Installation Condition Report (EICR) or Periodic Inspection Report (PIR) shall be carried out in accordance with the Health and Safety Authority (HSA) Guidance Note. It should be noted in the comments box on the certificate that this recommendation has been issued.

Where a REC is working on a distribution board and sub distribution boards are downstream of the distribution board being modified, only RCDs / RCBOs contained within the distribution board being modified shall be tested in accordance with the National Wiring Rules for Electrical Installations.

Where it is found that circuits cannot be de-energised in order to test RCDs / RCBOs, the REC shall note on the Test Record Sheet the reason why RCDs / RCBOs were not tested and transcribe this reason to the comments section of the certificate. It should also be recommended to the client / point of contact that all untested RCDs / RCBOs be verified as soon as possible during the next periodic Inspection /EICR of the premises .

Compliance and Co-operation by the REC

Registered Electrical Contractors are required to comply with the above listed requirements, which have been introduced in the interests of safety, and to assist the person responsible for the installation to be aware of potential pre-existing faults in the existing circuits. Safe Electric will oversee the implementation of these requirements to ensure full compliance.